|

In order to ensure long life and exceptional functionality all ATG rollers are produced using the highest quality materials and manufacturing processes. High grade steels are utilised for the roller bodies with all bearing and seal housings filled with a performance lithium grease to lubricate and safeguard against detrimental materials. The hard-wearing seals minimise rotational resistance on the shaft.

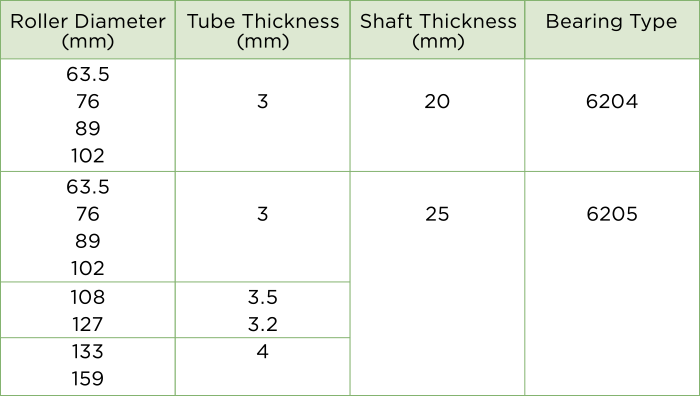

With continued quality inspections carried out throughout production all roller bearings have a minimum 40,000 working hour warranty. Bespoke options are also available upon request with a variety of different diameters and tube thicknesses.

|