Displaying items by tag: conveyors

|

|

ATG had a blast at Hillhead 2022.

It was great to be back at the world’s biggest working quarry event this June! |

With the event celebrating its 40th anniversary, and after a 4 year COVID induced hiatus, Hillhead 2022 was always going to be a celebration of all that is admirable about the quarrying, construction and recycling industries. Set in a working quarry, in the heart of Derbyshire, the exhibition confirmed its standing as the biggest event of its kind in the world.  Not only does Hillhead boast stand space for 600+ exhibitors in the Main Pavilion, Registration Pavilion and Quarry Area; it’s also home to four separate demonstration areas - Quarry Face, Rock Processing, Recycling and Registration. In these areas there was a variety of machinery in action including excavators, wheel loaders, dozers, screening buckets, tracked and skid-mounted crushers, screens, shredders, screens and washing equipment.  For ATG, Hillhead 2022 proved to be a resounding success, not only for showcasing our global sourcing expertise to our target markets but also being actively involved in sponsoring various areas of the exhibition. Our support included hosting the Hillhead Café, sponsoring the branded lanyards and goodie bags, and supplying thousands of cups to the various eateries across the site.  It was particularly rewarding seeing the attendees carrying the various goodies in their ATG & A-Trax branded bags whilst wearing their lanyards. We supplied 20,000 lanyards and 8,000 bags, all of which were distributed by the excellent staff in the reception pavilion.  In addition, not only did we have our ATG, Global Sourcing Specialists, stand in the main Pavilion we also had stands for ATG Conveyor Components division and for our crawler track system manufacturer, A-Trax. This ensured that all of our business interests were represented at ATG with our key Technical and Sales Teams available to answer questions about our goods & services.    This ensured we were able to effectively explain to visitors that ATG’s business model offers a host of advantages that are in complete synergy with our customers’ requirements. Not only does ATG supply parts and components to international OEMs across the world we also offer the following benefits:

There’s always great speculation about what the weather will be like at Hillhead. The general consensus is that it will rain cats and dogs or be glorious sunshine! Fortunately, the latter prevailed this time, with blue skies across the site for the entire 3 days. This made the Hillhead Café, sponsored by ATG Conveyor Components, the ideal place to retreat to for a little bit of rest and recuperation.  All in all, it was a fabulous three days at Hillhead 2022 getting back to having face to face meetings with existing customers and catching up with old friends. As ever, ATG’s unique business model proved to be extremely interesting to the many visitors who came to our stands. It was excellent to explain all of the benefits of working with ATG to continually deliver high quality sourcing solutions across the globe.  If you’d like to know more about what ATG can do for you and your business, please get in touch by filling out our Contact Form or giving us a call on +44 (0) 330 041 7076. Our Global Sales Director, Matt Cheetham, can also be found on LinkedIn by clicking here. |

Published in

News

|

|

ATG Conveyor Components Working with Centristic Ltd.

Part 1 of ATG Conveyor Components’ case study on Centristic’s installation at Mountsorrel Quarry in Leicestershire, United Kingdom. |

|

Tarmac Trading Ltd. are undertaking a major mechanical and electrical infrastructure installation at its Mountsorrel Quarry site near Loughborough. As part of the quarry’s consented extension, a new semi mobile primary crushing station is being installed along with material handling equipment to transfer extracted mineral from the new crushing location over to the secondary processing facility.

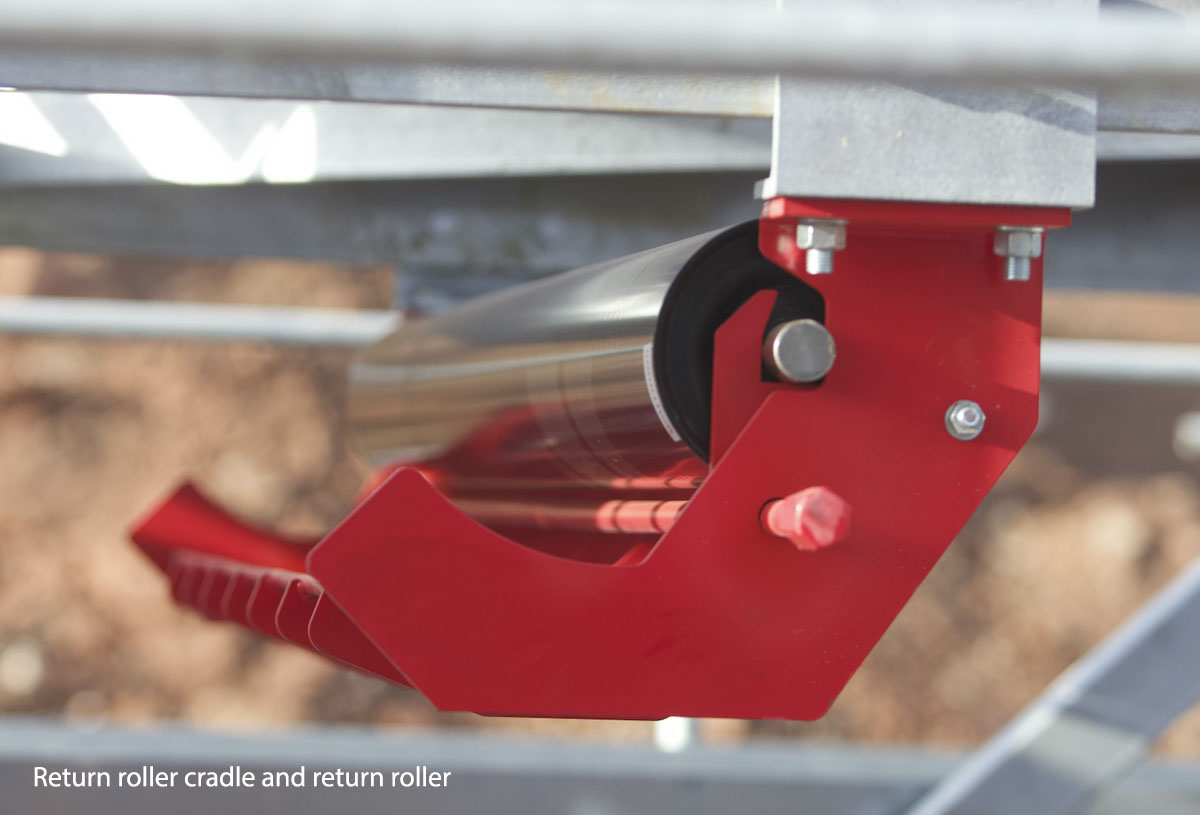

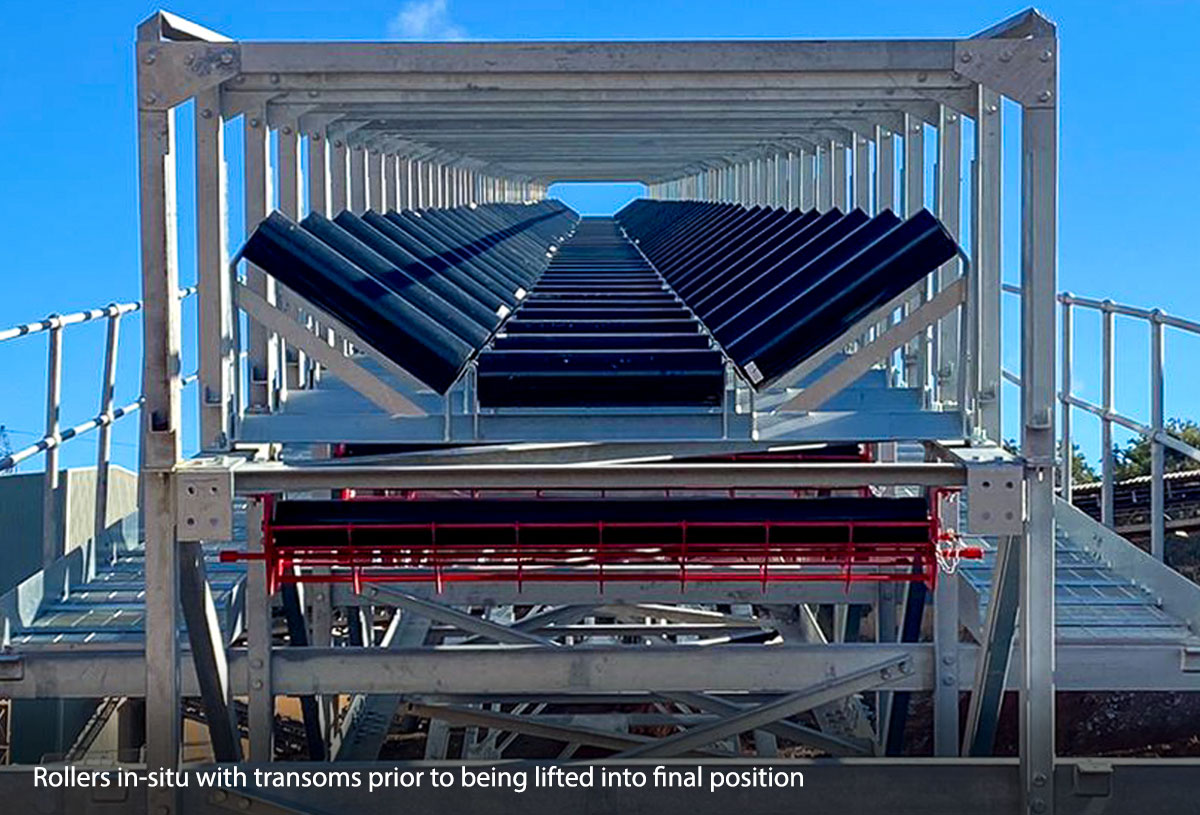

Centristic Ltd., a Devon based engineering business specialising in the design, manufacture, and installation of bulk material handling solutions to the quarry and material processing industry, have been commissioned to design, manufacture and install a primary conveying and screening scheme, transferring primary crushed mineral to a new screen house for grading and loading out, and also the onward transfer of material to the existing Secondary Plant. The new conveying system comprises of 4 conveyors, ranging from 1200mm to 1800mm wide belts, with the process running at 2500tph. ATG Conveyor Components have supplied a variety of products to Centristic for the various conveyor systems. These parts include rollers, return rollers, return roller cradles, and wear blocks.  All the conveyor components supplied by ATG are being shipped direct to Mountsorrel Quarry where the conveyor system is being constructed by the installation team from Centristic.   The return roller cradles are used on the elevated section of the conveyors or hard to get to areas to aid replacement, ensuring compliance with the relevant health and safety rules.   The rollers and return rollers supplied for the Mountsorrel installation feature a host of benefits including a heavy-duty construction, airtight seals, high concentricity and are maintenance free. High grade steels are used in the roller bodies with all bearings and seal housings filled with a high-performance lithium grease.  The steel gantry runs adjacent to the main conveyor allowing routine maintenance to take place on the elevated section of the system.  The scheme is progressing well with the conveyor installation planned for late 2021. Commissioning will take several weeks to complete with handover by Centristic expected to be in early 2022. ATG Conveyor Components are delighted to be part of this exciting project that will see the Mountsorrel Quarry continue to produce high quality stone for many years to come. For more information about any of ATG’s conveyor products please get in touch with Global Project Manager, Tony Hooker, through the contact form on our website or through his profile on LinkedIn. You can also give us a call on +44 (0) 330 041 7076. |

Published in

News

|

|

ATG Conveyor Components Always Delivers Quality

ATG Conveyor Components offer the complete conveying system solution |

|

ATG Conveyor Components was originally formed to consolidate global sourcing specialists, ATG’s conveyor systems division. Over the last few years, it has seen unprecedented growth, which has been down to a number of factors including the consistent supply of high quality product supported by a highly knowledgeable technical team and exemplary aftersales service.

With an extensive range, ATG Conveyors Components supplies rollers, field conveyors, disc return rollers, conveyor drums, impact rollers, power transmission, unit handling components and transoms. We also supply ancillary items such as cages, belting and fixings to give our customers the complete conveying solution whatever the application.  STANDARD ROLLERS All ATG rollers are designed to operate in the most challenging of environments, in most cases running for 24 hours a day, where efficiency and long service life are critical.

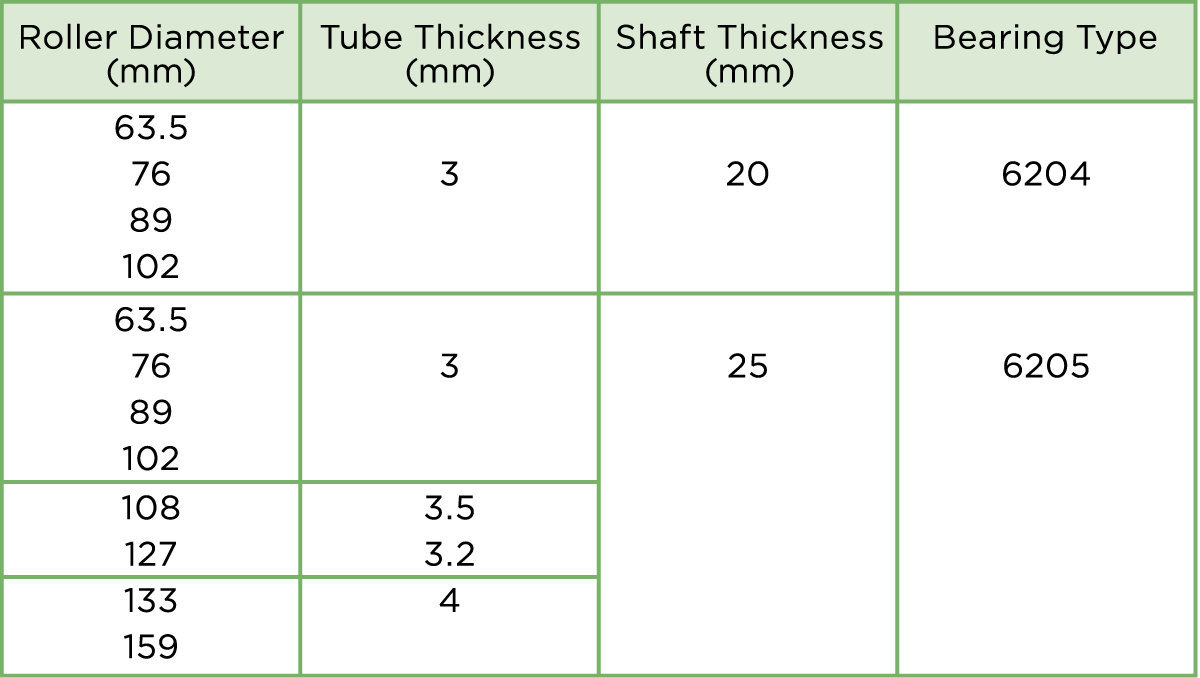

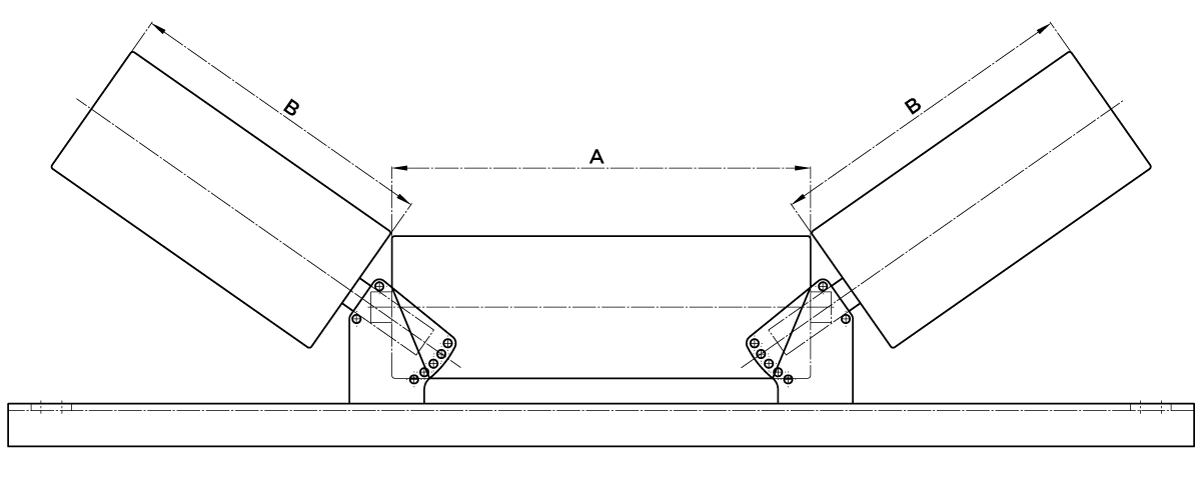

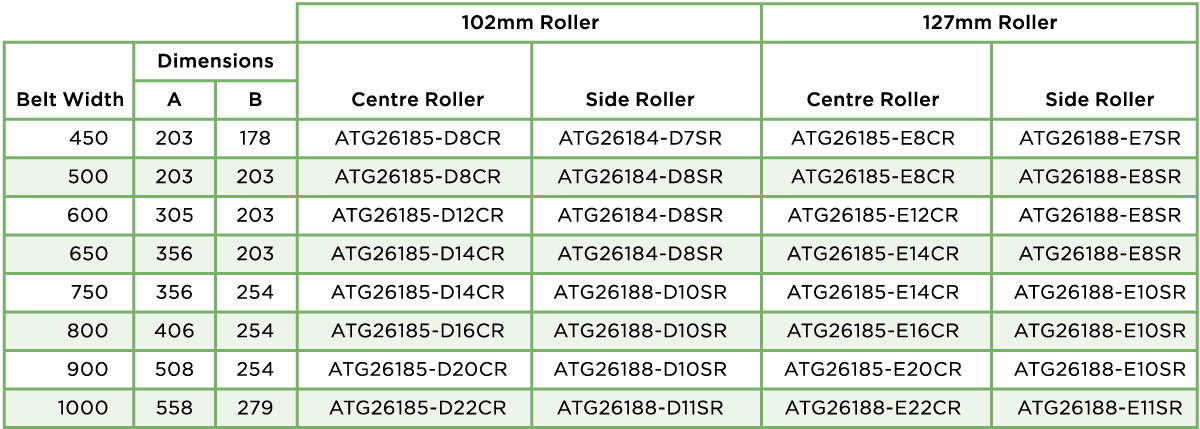

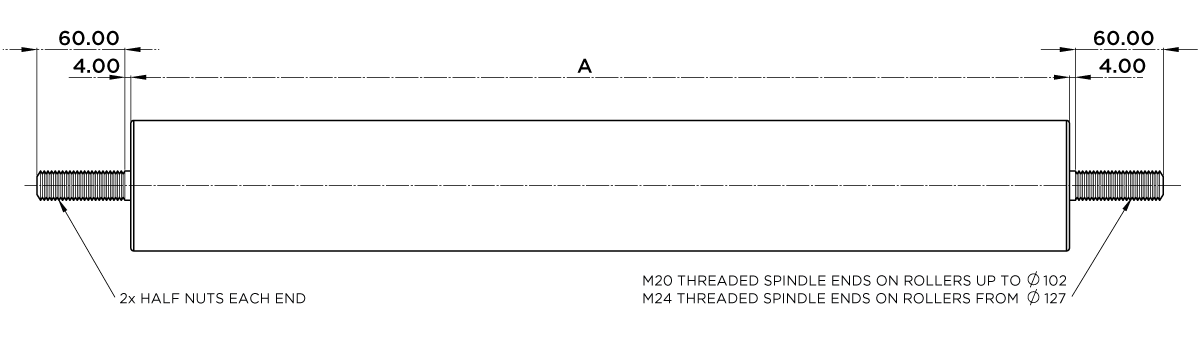

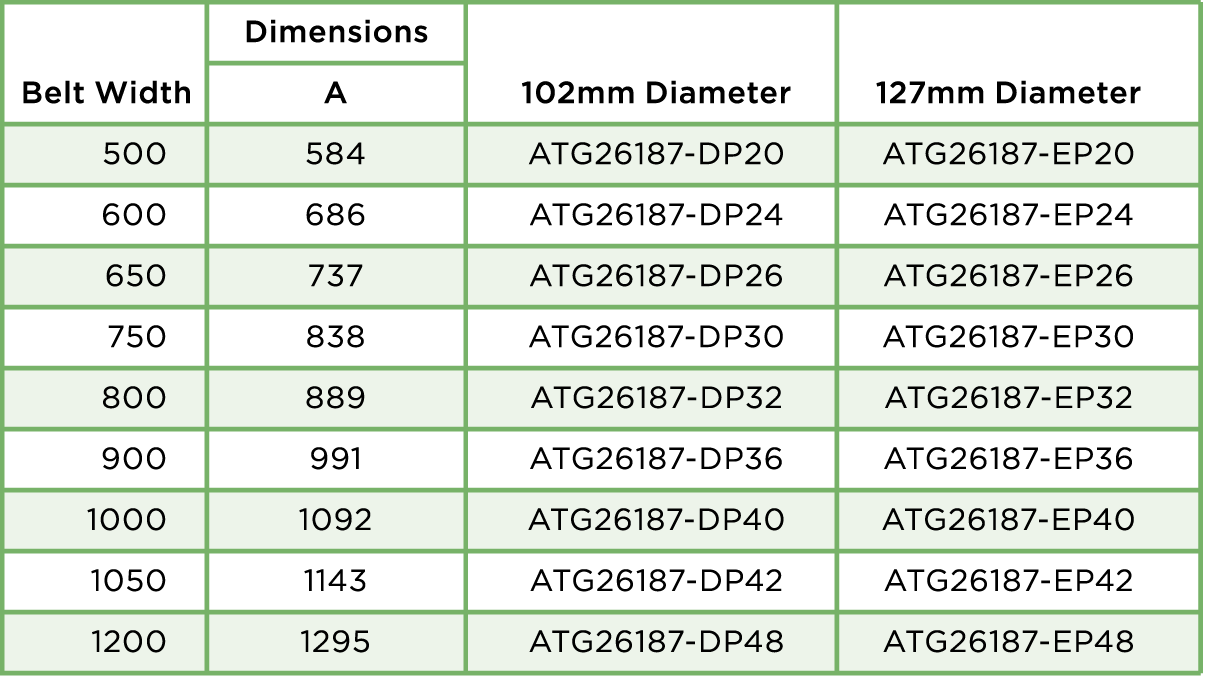

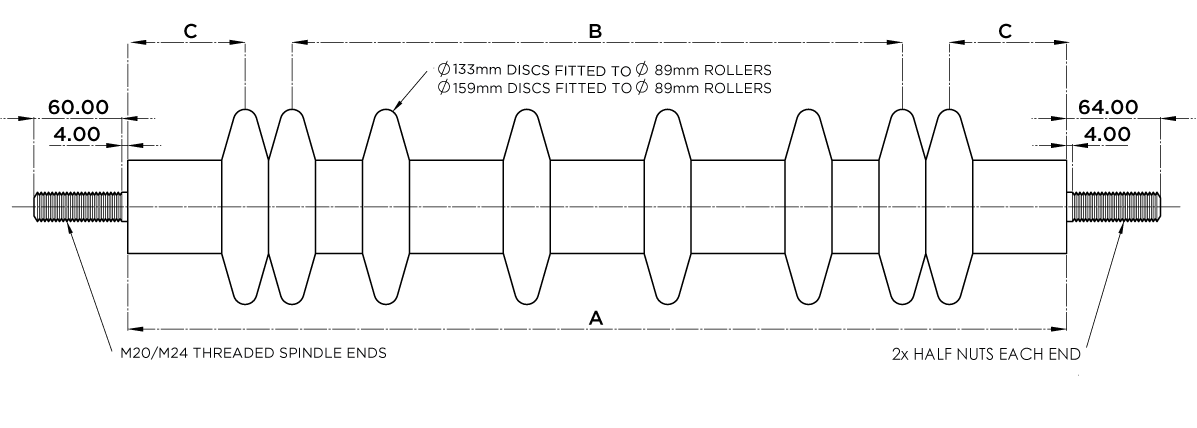

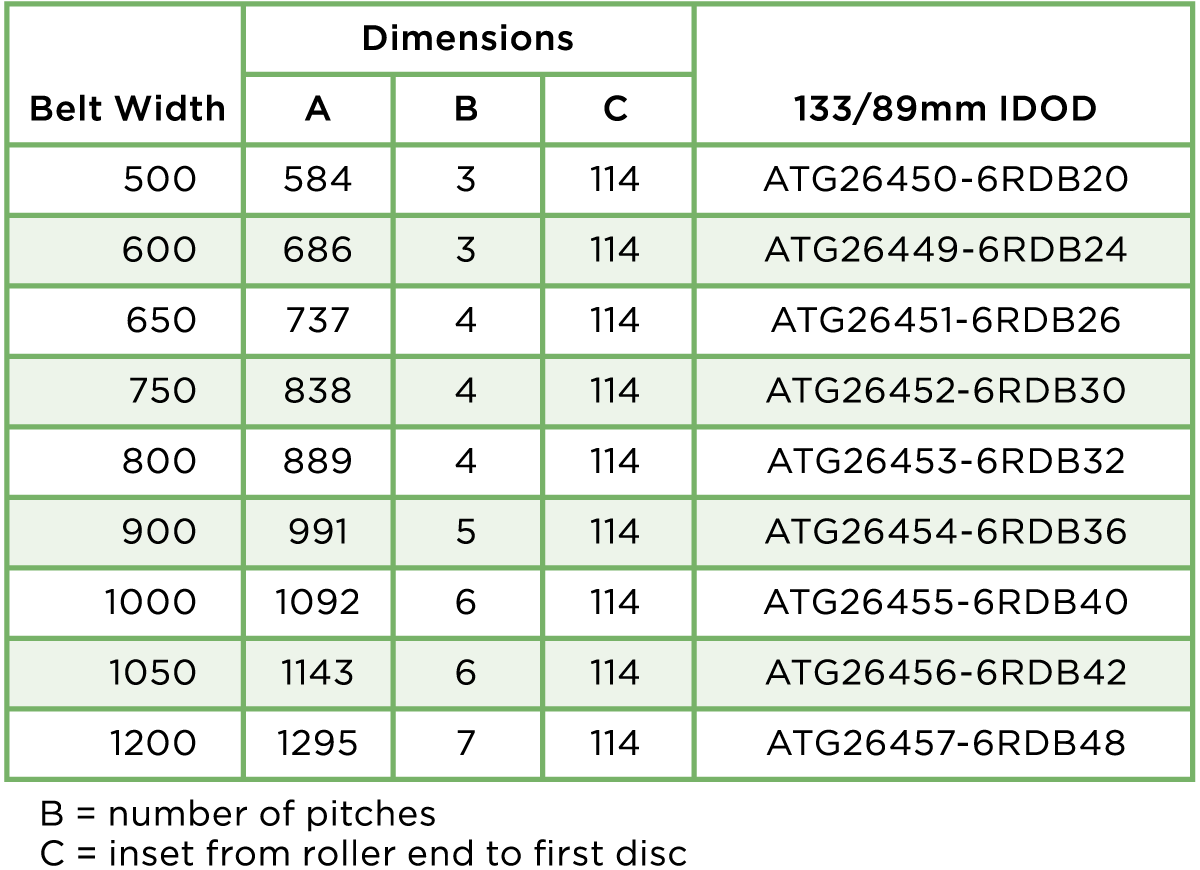

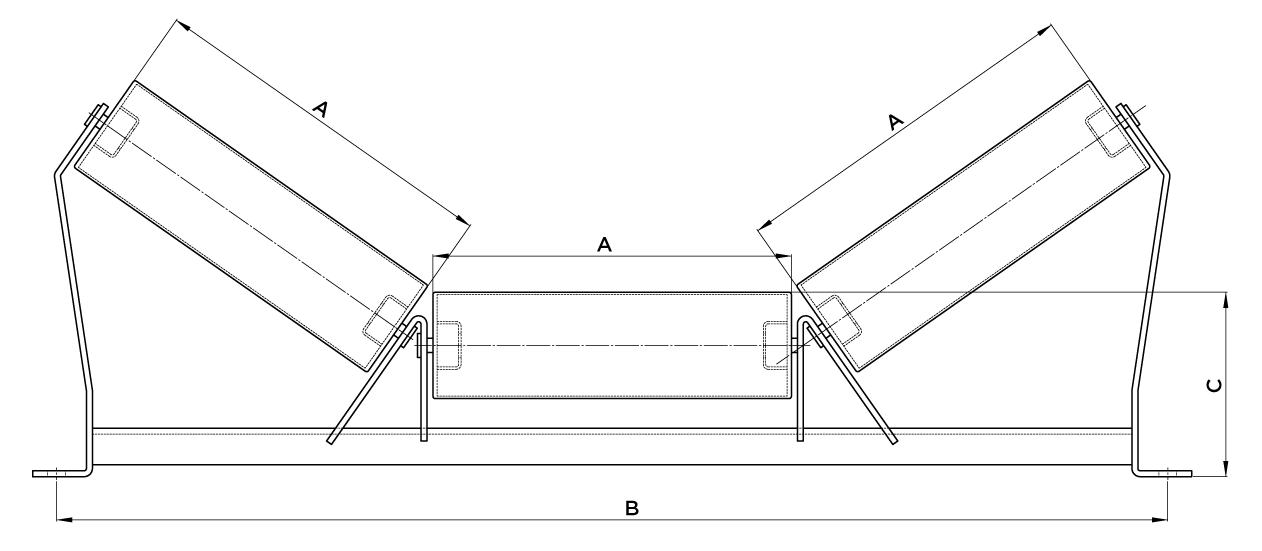

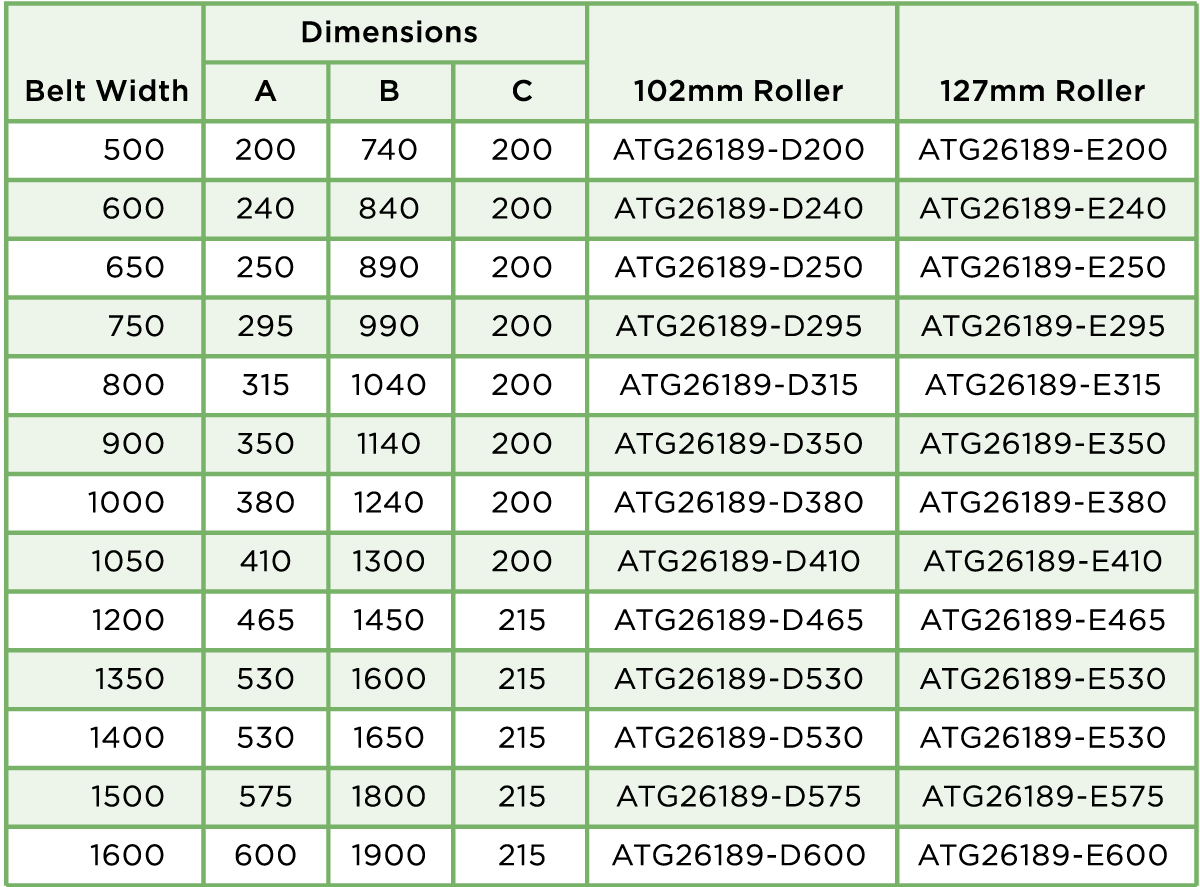

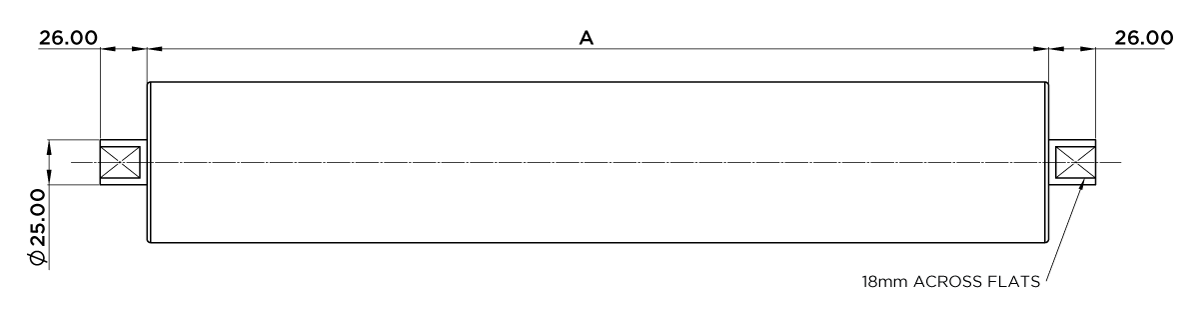

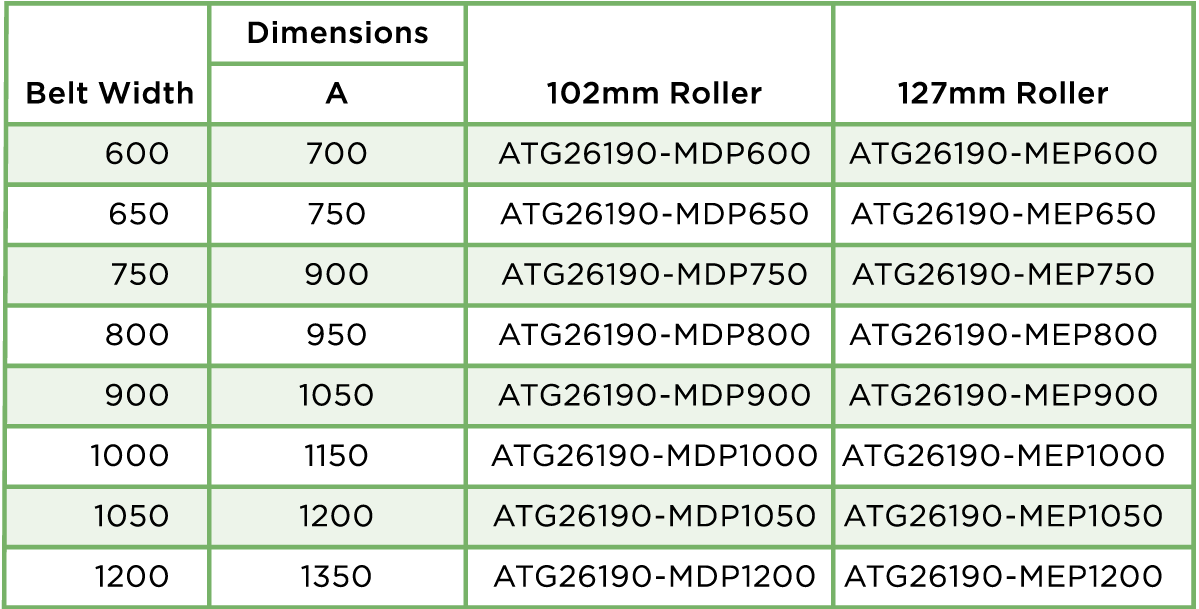

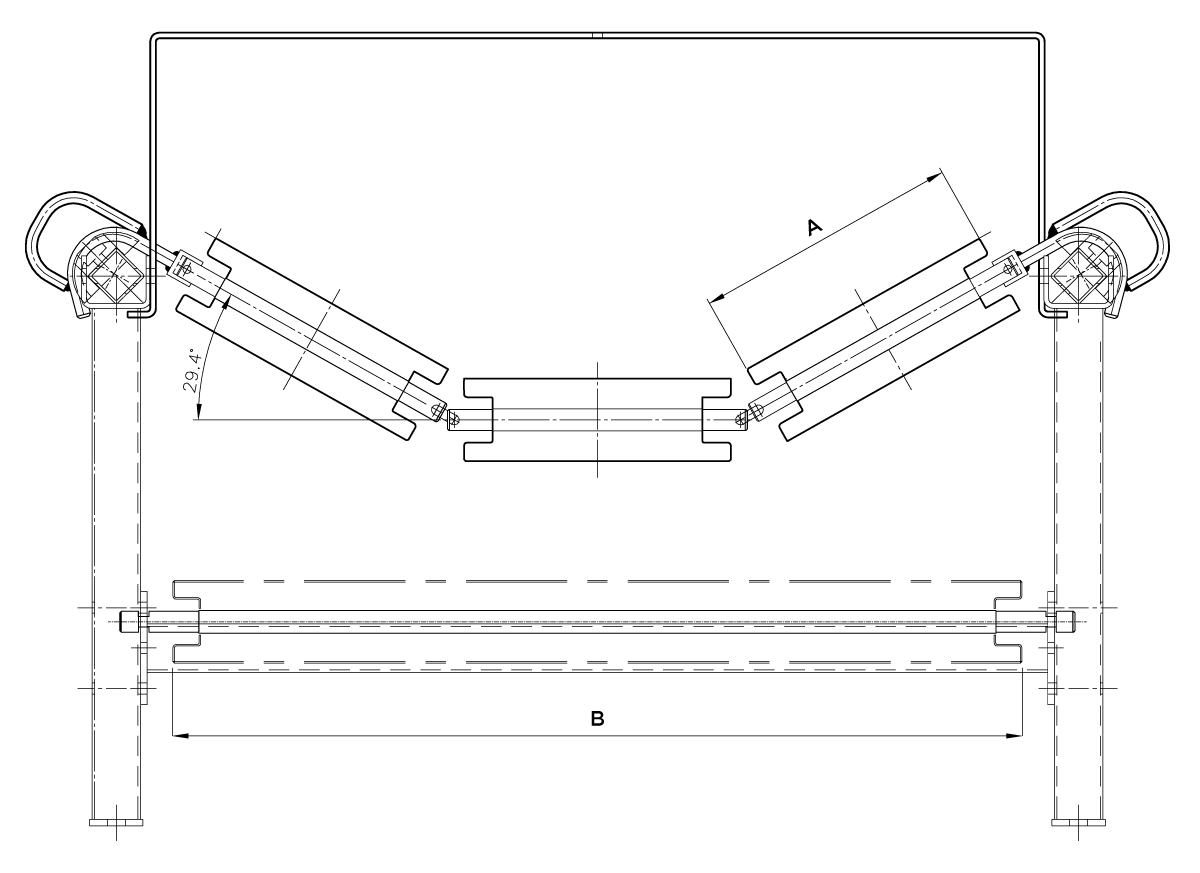

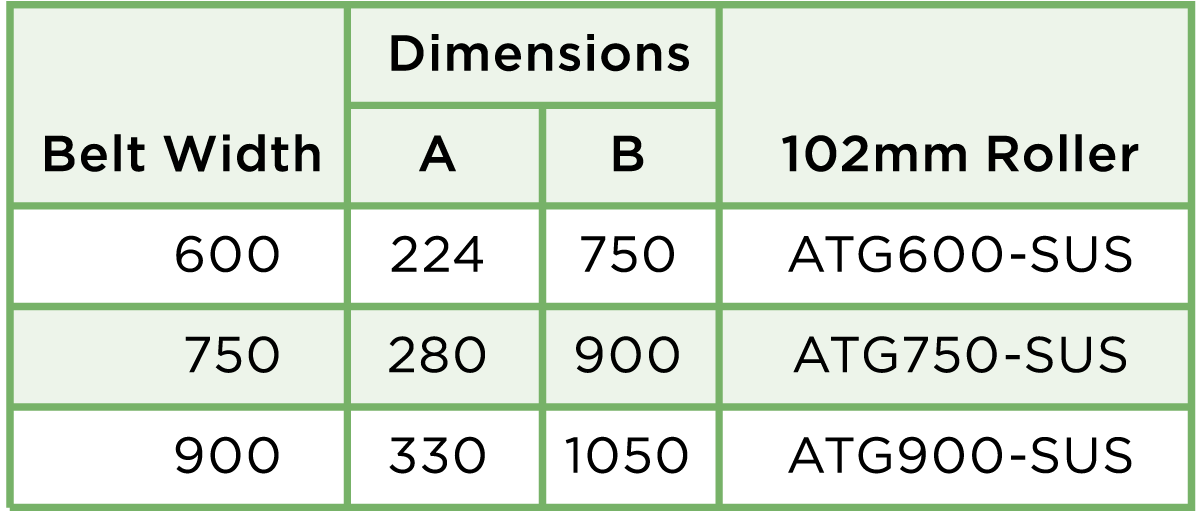

With continued quality inspections carried out throughout production all roller bearings have a minimum 40,000 working hour warranty. The table below showcases our standard size rollers. Bespoke options are also available upon request with a variety of different diameters and tube thicknesses.  ADJUSTABLE TROUGH SETS AND RETURN ROLLERS ATG Conveyor Components supply a wide range of adjustable trough sets and return rollers for a variety of applications for the mining, material processing, waste recycling and crushing & screening industries. Below follows a selection of these items with technical and dimensional detail on each. VARI ANGLE – 3 ROLL TRANSOM Designed for light to medium applications our Vari Angle Sets feature an adjustable roller which allows the wing idler to be set at 20°, 30°, 40°, 50° and 60°. This low rolling resistance design is compatible with one of the most universally used systems on the market and is available with 102mm and 127mm diameter rollers. Rollers can be manufactured with either 20mm or 25mm bearings as standard. All transom frames can be supplied either painted black, galvanised or self-colour to suit customers’ requirements.   VARI ANGLE – RETURN ROLLERS ATG Conveyor Components offer a wide range of Vari Angle Return Rollers ranging from 63.5mm up to 168mm diameter to suit customers’ individual requirements and applications. We can cater for all belt widths.   VARI ANGLE – DISC RETURN ROLLERS Disc Return Rollers are mainly used on conveyor systems where wet or sticky materials can build up on standard return rollers. The ring design minimise detritus collecting on the roller prolonging product life and increasing system efficiency.   FIXED – 3 ROLL TROUGHING ROLLER SET Designed to be used in more heavy-duty applications than the adjustable sets these 3 Roll Troughing Sets have a fixed angle. ATG Conveyor Components can cater for all roller diameters and belt widths to suit customers’ individual requirements and applications. All transom frames can be supplied either painted black, galvanised or self- colour as per customers’ specifications.   FIXED RETURN ROLLER For use in conjunction with the Fixed Troughing Sets these heavy-duty Fixed Return Rollers come in 102mm & 127mm diameters. Rollers are supplied with a powder coated finish.   SUSPENDED SETS Designed for ease of installation our range of Suspended Sets are used primarily in field conveyor systems. With excellent low rolling resistance, good lateral and ground clearance this versatile design is supplied with 102mm or 127mm rollers and is compatible with belt widths of 600mm to 900mm.   Whether you’re looking for bespoke parts or a large volume of identical product ATG Conveyor Components will work with you to feed into your installation timetables. We can also work to your scheduled maintenance programmes to ensure downtime is kept to an absolute minimum of any plant or conveying systems. For more information please get in touch with Global Project Manager, Tony Hooker, or Business Development Manager, Gillian Miller. You can also get in touch by filling out our Contact Form or giving us a call on +44 (0) 330 041 7076. |

Published in

News